- 2 7axes CNC turning + milling center “Bumotec S-191FT” + second stage spindle, 90 tools, automated bar loader Ø<50mm.

- 2 5axis CNC milling center with automatic feeder “Fanuc Robodrill T21iC”, 15’000 rpm, 21 tools

- 1 5axis CNC milling center “Mori Seiki NV4000 DCG”, 12’000 rpm, 40 tools

- 1 5axis CNC milling center “Fanuc Robodrill T14iB”, double spindle 12’000 rpm et 60’000 rpm, 14 + 8 tools

- 5 5axis CNC milling center “Fanuc Robodrill” 24’000 rpm, 21 tools

- 3 3axis CNC milling center “Fanuc Robodrill” 15’000-24’000 rpm, 21 tools

- Conventional milling

130 years of passion for progress give incomparable results

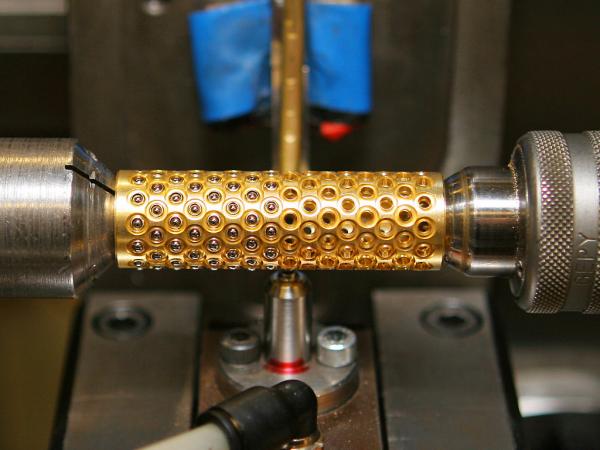

Progress in the service of the human, for more than a century. Piguet Frères strives to provide solutions for the machining of extra-hard materials, components and microtechnical subsystems in uncompromising quality standards that contribute to the history of your product.

With machines that adapt to your needs and search for the best possible solution, we focus on reliability, the basis of the enriching collaboration we have with our customers and partners.

Materials we manufacture

- Steel and stainless steel (medical grade)

- Copper alloys, brass, bronze, Arcap

- Aluminium

- Nickel alloys: Inconel, Monel, Hastelloy

- Special alloys, ...

- Sapphire and rubis or Corindon Al2O3

- Ceramics: Zircone ZrO2, Macor, Silicium carbide SiC

- Metallic carbides

- Quartz SiO2 (silice)

- Glass

- PEEK, PTFE, PCTFE, PI Vespel, PEI, POM, PPSU, TPX, PA, PVDF, PP, FEP, etc...

- Composite (carbon fiber)